SUSTAINABILITY

A technological

challenge

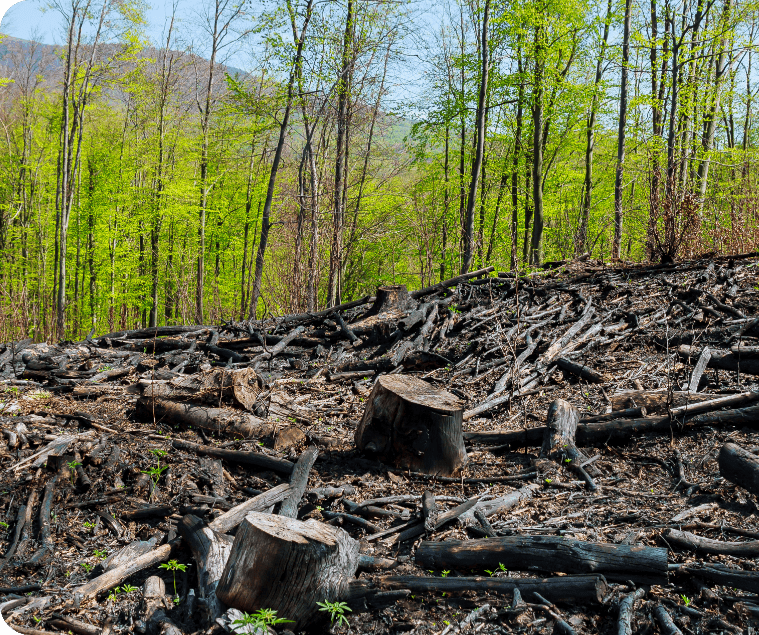

We live in a world of great progress where technologies help us deliver services faster and more efficiently. For many years, the natural environment has been over-exploited due to excessive greed for profit, lack of respect for nature and short-sighted thinking that natural resources are infinite. Now is the time to change that thinking.

LIBRA PARTNERS’ mission is to become a key player in sustainability, a concept that will undoubtedly shape the company’s guidelines in the coming generation. The circular economy is a philosophy of systemic organization inspired by living beings, aiming to change the linear economy (produce, use and dispose) to a circular model, as in nature.

The outdated linear system of our economy (extraction, production, use and disposal) has reached its limits. We are beginning to witness the depletion of a range of natural resources and fossil fuels. Alternatively, the circular economy proposes a new social model that exploits and optimizes the flows of stocks and materials, energy and waste. The goal is to achieve maximum resource efficiency.

The implementation of business processes of the wood industry in the European Union is becoming more and more difficult. The situation of this sector is becoming more and more unknown every year, among others due to unforeseen increases in the prices of wood products, interruption of the regular raw material supply chain caused by the war in Ukraine and mass exports of native wood outside our country.

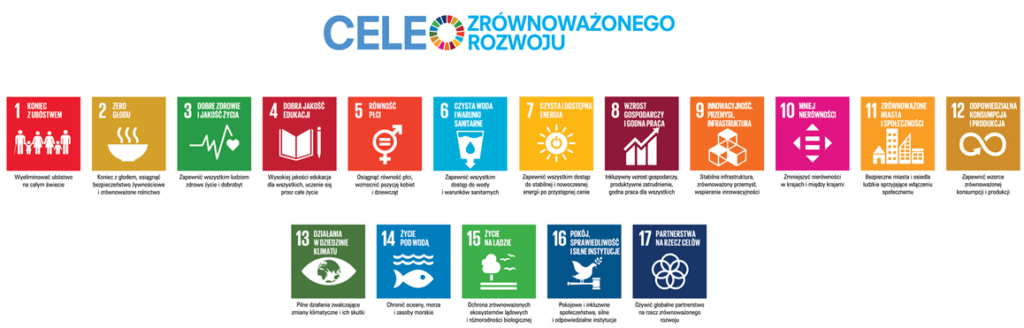

In addition, the wood industry has a negative impact on the natural environment, in the years 2010-2015 the area of forest areas in the world decreased by 3.3 million hectares. In 2021-2022, the prices of wood products increased on average from 60% to as much as 400%, and the price of a wooden pallet increased by almost 300%. The business cycle in this industry also affects ordinary citizens, due to the high price of wooden pallets, the price of transport is increasing, and this is reflected in the prices of subsequent products. Please refer to the Sustainable Development Goals of the 2030 Agenda, adopted by all 193 UN member states by resolution of the General Assembly on September 25, 2015 in New York.

Selected goals of the sustainable development policy, confirming the compliance of our project with the goals of the 2030 Agenda.

Over the next 40 years, the world's use of materials such as biomass, fossil fuels, metals and minerals will double, and the amount of waste generated annually will increase by 70%.

SUSTAINABILITY

Circular economy

Over 200 tons of HDPE waste – this is the amount of waste that is recycled monthly, from which our pallets are made.

Thanks to our efforts in the production of recycled plastic pallets that weigh less than standard wooden pallets, our customers reduce CO2 emissions to the atmosphere by over 300 tons per month.

So many trees are needed per month to absorb additional CO2 emissions in the case of using wooden pallets instead of LIBRA PARTNERS pallets to the environment.

Over 100.000 m3 of wood – this is how much wood is used monthly for the production of pallets in Poland.

it is like a forest of about 110 hectares

SUSTAINABILITY

carbon footprint

MONTHLY PALLET PURCHASE

500 PCS

6,060 TONS LESS CO2

1.000 PCS

12,120 TONS LESS CO2

2.000 PCS

24,240 TONS LESS CO2

6.000 PCS

60,600 TONS LESS CO2

10.000 PCS

121,120 TONS LESS CO2

Make your company compliant with the Sustainable Development and ESG policy. Prepare your company for non-financial ESG reporting now. Changing pallets from wooden to plastic LIBRA PARTNERS is the simplest solution to significantly reduce CO2 emissions and carbon footprint into the atmosphere

LIBRA PARTNERS, thanks to the production of pallets from recycled HDPE raw material, adheres to the principles of Sustainable Development, Circularity and the 6R Principles.

The key element of the REFUSE principle is minimizing the consumption of raw materials and energy, which is of key importance for environmental protection and reducing negative effects on the environment, and its essence is to strive to reduce the amount of waste and pollution, as well as the consumption of raw materials and energy by changing habits and choosing products and services that are more efficient and sustainable.

Recycled HDPE plastic pallets are in many ways an improved substitute for wooden EUR pallets. By using recycled material instead of wood like standard wooden pallets, we reduce deforestation. Consumer awareness should be promoted to make sustainable purchases. According to statistical data, over 100.000 m3 of wood – that’s how much wood is obtained monthly in Poland for the production of wooden pallets. it’s like a forest of about 110 hectares. Between 2010 and 2015, the world’s forest area decreased by 3.3 million hectares.

The key element of the REDUCE principle is minimizing the consumption of raw materials and energy, which is of key importance for environmental protection and reducing negative effects on the environment, and its essence is to strive to reduce the amount of waste and pollution, as well as the consumption of raw materials and energy by changing habits and choosing products and services that are more efficient and sustainable. The purpose of this principle is to promote a more sustainable approach to consumption, which is beneficial to both the environment and the economy.

Thanks to the monthly production of recycled pallets, LIBRA PARTNERS reduces CO2 emissions by 303 tons per month. This is because the weight of the LIBRA PARTNERS plastic pallet is 9 kg instead of 25 kg. Thanks to this difference in weight, transport with lighter pallets is more sustainable because the means of transport burns less fuel, and in addition the raw material used for the production of pallets is recycled. Assuming that one tree absorbs 0.5 kg of CO2 per month, it should be emphasized that if EUR wooden pallets are used instead of LIBRA PARTNERS plastic pallets, an additional 600,000 are needed.

The essence of this principle is to promote a long and productive life of products and raw materials, to reduce their disposal and to minimize waste and pollution. By reusing products and raw materials, you can increase their value, reduce costs and reduce the need for raw materials, thus reducing the negative impact on the environment. Reuse is part of a broader approach to sustainable management that promotes the long-term and more efficient use of resources.

Due to the fact that pallets made of plastic are much more durable compared to wooden pallets, they can be used 10 times longer than wooden pallets, which under the influence of weather conditions lose their properties and quickly degrade. According to research conducted by the Institute of Materials Engineering in Warsaw, the average life cycle of a wooden pallet is 6-7 cycles of loading/unloading, then such a pallet requires repair or is useless. In the case of plastic pallets, where there is no degradation process as a result of the influence of weather conditions on the pallet – the life cycle of a plastic pallet is about 60-70 loading / unloading cycles, and it should be emphasized that after this time the pallet is 100% recyclable which reduces the amount of waste in the environment.

It refers to recovering raw materials and energy from waste instead of throwing it away. The natural goal of this principle is to reduce waste and the need for primary raw materials. The RECOVER process may involve various methods such as:

1. Recovery of energy from waste – e.g. by burning waste in power plants or producing biogas from organic waste.

1. Recovery of energy from waste – e.g. by burning waste in power plants or producing biogas from organic waste.

3. Waste management – e.g. by composting organic waste and turning it into an organic substance that can be used as fertiliser.

Thanks to the RECOVER process, it is possible to reduce the amount of waste that goes to landfills, as well as reduce the need for primary raw materials. In this way, waste can also be used as a source of energy and raw materials, which is beneficial for the environment and the economy.

Due to the fact that as a socially responsible and ecologically aware company, we want our production process to also stand out with the highest standards in the field of environmental management. We do this through a business model focused on ZERO WASTE. Due to the fact that the raw material from which the pallets are made is 100% recyclable, we guarantee our customers the collection of used and damaged pallets purchased from LIBRA PARTNERS. There is no waste in this business model, there is a Circular Economy model.

The purpose of this principle is to reduce the amount of waste that ends up in landfills and, similarly to the RECOVER principle, to reduce the need for primary raw materials. The RECYCLE process consists in sorting waste and processing it into raw materials that can be reused in the production process. Examples of raw materials that can be recycled include: paper, plastics, metal, glass and other materials. After sorting, the waste is transformed into new raw materials such as waste paper, plastic and metal, which can be reused in production. Recycling is important because it reduces the amount of waste that ends up in landfills and reduces the need for primary raw materials. In this way, you can also protect the environment and save natural resources.

Thanks to the purchase of HDPE raw material regranulates from specialized companies from which LIBRA PARTNERS produces pallets, we give a second life to the products from which the purchased regranulate is made, e.g. packaging of washing gels, fabric softeners, plastic packaging of milk and many others. There is a model of the Circular Economy here.

SUSTAINABILITY

Produktlebenszyklusbericht

An LCA (Life Cycle Assessment) analysis determines the environmental impact of a product or system throughout its life cycle and identifies the most carbon-intensive stages of the manufacturing process. The steps in an LCA analysis include defining the purpose and scope, life cycle analysis assessing the environmental impact, and interpreting the results.

In August 2023, an analysis of Libra Partners was published by Envirly – a leader in measuring the carbon footprint of products on our palette. We encourage you to read the results presented in this analysis.